When it comes to welded and redrawn stainless steel tubes in premium quality, Schoeller plays a leading role on the European market.

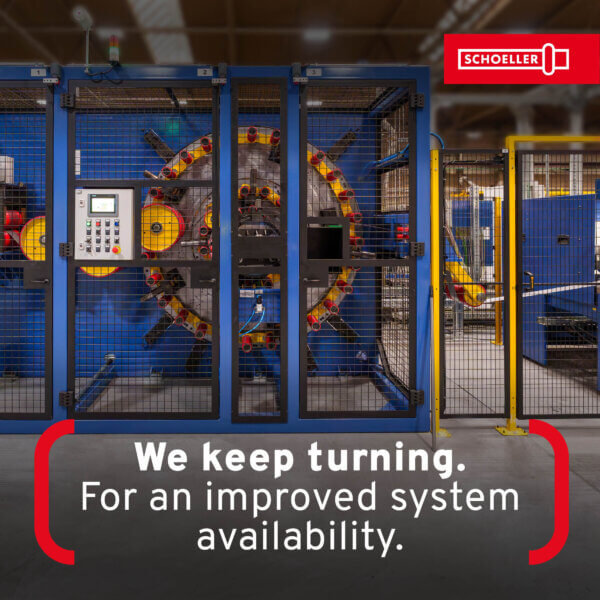

In addition to central focus points such as the highest level of consulting expertise and customer-centered development work, more efficient and better processes are significant goals of our current site development. As part of the development of a competence center in our laser welding area, we were able to reduce the ratio of scrap and significantly increase system availability by installing strip accumulators in the medium size range.

We will also be able to use these positive effects on production efficiency for our large laser welding lines soon. Two strip accumulators were delivered to Hellenthal at the beginning of October: One was able to go into production operation on schedule after just a few days, while the second system is expected to go into operation in the third quarter of 2024 as part of the standardization and modernization of another laser.

As a result of these modernization measures, we will achieve a significant reduction in scrap and improved system availability.

Everything. For the best solutions.