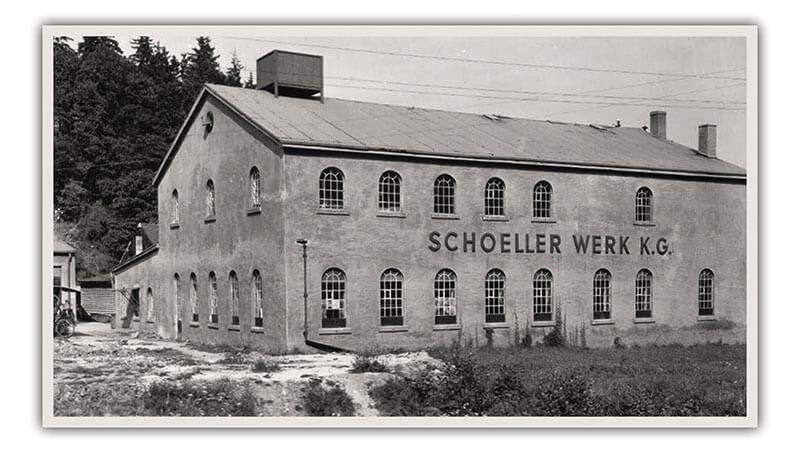

Foundation of Schoeller Werk GmbH at the current location in Hellenthal

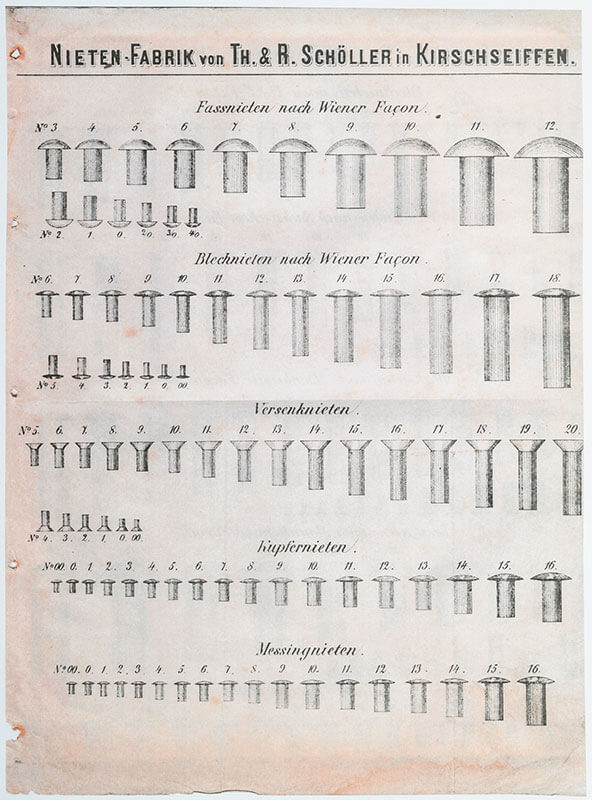

Schoeller Werk is a pioneer in the industry by using the first automatic nailing machine for wire meshes and rivets

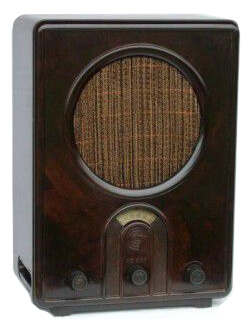

First fine-precision fabrication of cathodes for radio valves and cannula

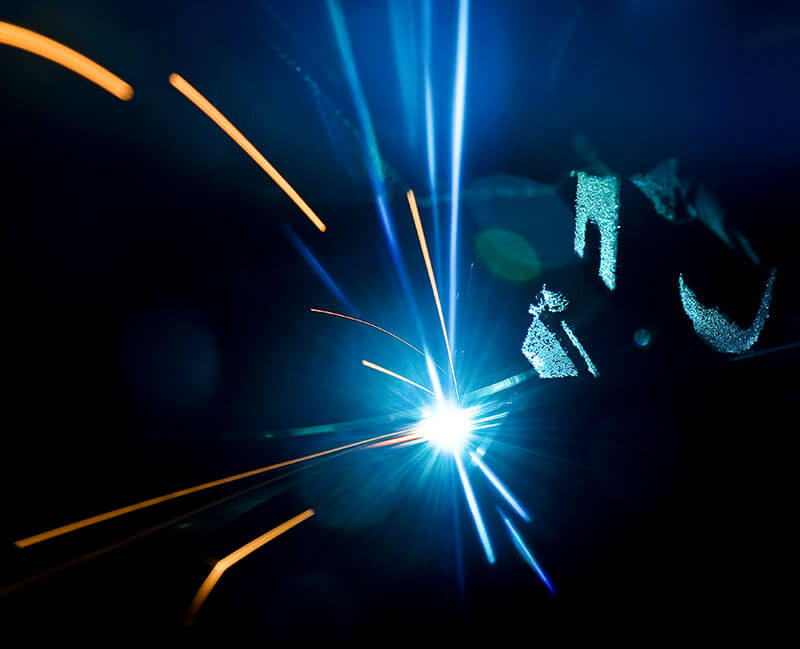

Commissioning of the first tube welding lines for the manufacture of longitudinally welded, rust-free stainless steel tubes in the TIG welding process

Schoeller Werk is the first manufacturer with a weld seam quality of 1.0 for TIG welded tubes made from austenitic steel

Schoeller Werk begins the series production of tubes made from ferritic and austenitic steel for exhaust systems in the automotive industry

Introduction of laser welding technology

Introduction of ultrasonic testing

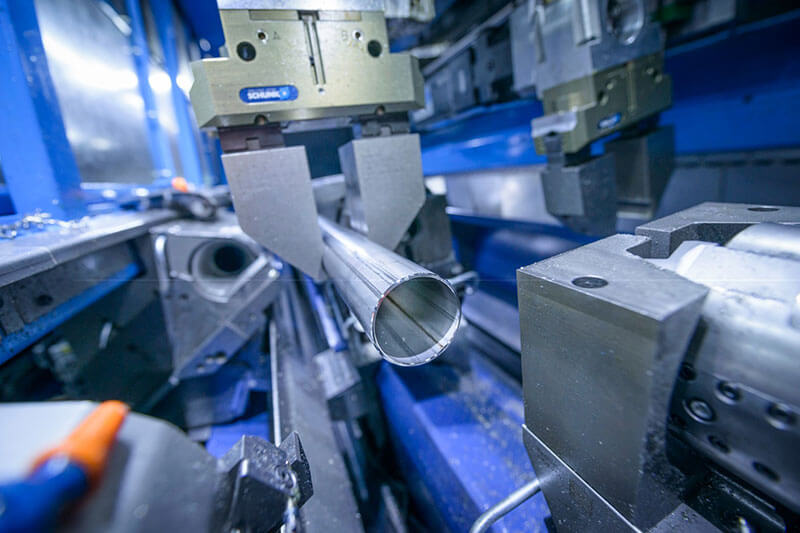

Commissioning of high performance sawing systems with CNC end facing

Acquisition of the engineering service provider ID Ingenieure & Dienstleistungen GmbH

Purchase of AK Feinrohr GmbH, specialist for cold redrawn precision tubes

Positioned for the future.

From wire mesh and cathodes to premium tubes.

Since the company was founded in 1827, Schoeller has continuously developed, responding to ever-changing market requirements and expanding its leading role in the industry. But one thing has remained the same: we have always seen ourselves as a family business and have been practising these values since day one.

Always one step ahead

As far back as 1863, we lived up to our pioneering reputation by producing wire mesh and rivets with one of the first automatic nailing machines. Achieving the best possible product results by using the latest technology has been an integral part of our corporate practice ever since.

Another key factor is the constant expansion and optimisation of our solution portfolio. In 1932, for example, Schoeller began the first precision manufacturing of cathodes for radio valves and hypodermic needles. In 1959, we began producing longitudinally welded stainless steel tubes using the TIG welding process. Finally, in 1965, we were the first producer to manufacture TIG-welded tubes made of austenitic steels with weld quality 1.0.

Precision tubes for every industry

Because industries and sectors are constantly changing, we are also in a constant state of transformation. This is the only way to meet all the latest demands of our customers and partners. For example, the year 1975 marks an important point in Schoeller’s cooperation with the automotive industry. What began then with the series production of tubes made of ferritic and austenitic steels for automotive exhaust systems has since become a real success story – our solutions are now used by manufacturers and suppliers for a wide range of components.

But our development is not just a question of technology (such as the introduction of laser welding in 1991 or ultrasonic testing in in 2009). Together with Schoeller Feinrohr GmbH and ID Ingenieure & Dienstleistungen GmbH, Schoeller Werk in Hellenthal forms the Schoeller Group. With the resulting synergies, we can offer our global customers comprehensive solutions from a single source.